Roar Solutions for Beginners

Roar Solutions for Beginners

Blog Article

Things about Roar Solutions

Table of ContentsThe Greatest Guide To Roar SolutionsThe Roar Solutions DiariesThe 5-Second Trick For Roar SolutionsSee This Report on Roar Solutions

The equipment register is a comprehensive data source of devices records that includes a minimum set of fields to identify each item's place, technological criteria, Ex-spouse category, age, and environmental data. This info is crucial for monitoring and taking care of the tools successfully within dangerous locations. On the other hand, for periodic or RBI tasting inspections, the grade will certainly be a mix of Detailed and Close assessments. The proportion of Comprehensive to Shut examinations will be established by the Tools Danger, which is analyzed based on ignition danger (the chance of a source of ignition versus the probability of a combustible atmosphere )and the harmful area category( Zone 0, 1, or 2). This variation will certainly likewise influence the resourcing requirements for work prep work. When Great deals are defined, you can create sampling plans based upon the sample size of each Lot, which describes the variety of random equipment things to be evaluated. To figure out the needed example size, 2 facets need to be examined: the size of the Lot and the category of examination, which indicates the level of effort that must be used( lowered, normal, or boosted )to the assessment of the Lot. By incorporating the classification of evaluation with the Whole lot size, you can then develop the appropriate denial criteria for a sample, meaning the allowable number of defective items located within that example. For even more information on this procedure, please refer to the Power Institute Guidelines. The IEC 60079 conventional recommends that the maximum interval in between evaluations must not exceed three years. EEHA inspections will likewise be performed outside of RBI campaigns as part of arranged maintenance and tools overhauls or repair work. These assessments can be attributed towards the RBI example sizes within the impacted Whole lots. EEHA evaluations are conducted to determine faults in electric equipment. A weighted scoring system is important, as a single tool might have numerous mistakes, each with varying levels of ignition danger. If the combined rating of both evaluations is less than two times the mistake score, the Whole lot is deemed acceptable. If the Lot is still taken into consideration inappropriate, it has to undergo a full evaluation or reason, which may cause more stringent inspection protocols. Accepted Lot: The reasons of any kind of faults are determined. If an usual failure mode is located, added tools might require examination and fixing. Mistakes are identified by intensity( Security, Stability, House cleaning ), ensuring that urgent concerns are evaluated and attended to promptly to minimize any kind of influence on safety or procedures. The EEHA database need to track and tape the lifecycle of faults in addition to the restorative actions taken. Implementing a robust Risk-Based Assessment( RBI )technique is critical for making certain compliance and safety in taking care of Electric Equipment in Hazardous Areas( EEHA). Automated Mistake Scoring and Lifecycle Administration: Effortlessly manage faults and track their lifecycle to boost inspection precision. The introduction of this support for risk-based assessment further enhances Inspectivity's placement as a best-in-class service for governing compliance, along with for any kind of asset-centric assessment use situation. If you are interested in finding out more, we invite you to request a demonstration and find how our option can transform your EEHA administration procedures.

With over one decade of consolidated Ex experience (IECEx/ATEX, EEHA), Saipex began to advertise the value of competence of all workers associated with the Hazardous Area area in 2019. In 2021, our partnership with IndEx and Technology Skill International (TSI) marked a turning point in the Saipex roadway to proceed Ex lover improvement.

All About Roar Solutions

In terms of explosive danger, a hazardous area is an environment in which an explosive environment exists (or may be anticipated to be present) in amounts that call for unique precautions for the building and construction, installation and usage of devices. In this short article we check out the difficulties encountered in the office, the danger control steps, and the called for expertises to work securely.

(https://www.blogtalkradio.com/roarsolutions)

These compounds can, in particular conditions, develop eruptive atmospheres and these can have major and tragic repercussions. Many of us are familiar with the fire triangular eliminate any type of one of the three aspects and the fire can not take place, but what does this mean in the context of unsafe locations?

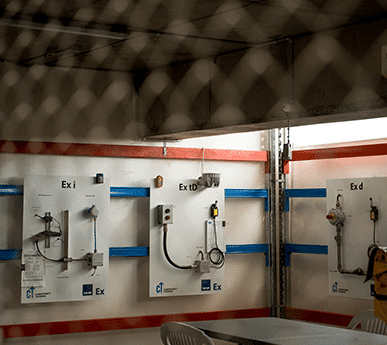

This is after that validated via examination and screening and is protected throughout the life of the installation by utilizing the right maintenance strategies, supplemented by routine assessment. When all these actions are taken, they ought to additionally be recorded. The verification dossier includes details such as the dangerous area category drawing, makers' paperwork, devices qualification, style drawings and computations, inspection documents, and documents of a person's expertise and proceeding specialist advancement (CPD), such as through ECA's eCOMS software.

The Of Roar Solutions

It is essential that trainees understand and have a comprehensive understanding as to what precisely makes up a hazardous location. The pupil should likewise understand why training is essential before trying to tackle work or defining equipment right into a hazardous area. These areas are also called classified locations and are specified as areas which have a high chance of an explosion due to the fact that of the possible presence of flammable gases, vapors, dusts etc.

Industries which contain harmful areas are now demanding that electric employees that are specifying or functioning in these locations should have a dangerous location credentials that considers them proficient. Jobs in these industries are extremely gratifying so you need to be prepared. To satisfy this need for the market, nationally identified training in Certificate IV in Hazardous area Electrical and EEHA training on the advancement of experienced specialists.

The 4-Minute Rule for Roar Solutions

Tech Skills Australia is a Registered Training Company giving you with one of the most economical and quickest method acquiring your certification - eeha training. Our instructors are sector qualified and have several years of process experience. Our training courses have helped hundreds of people from company managers to everyday staff members in acquiring a strong hang on this not so complicated but high danger training

The training additionally consists of determining the harmful locations, resources of explosion and the residential properties of unsafe products along with the responsibilities and features of all parties, laws, systems, standards and technique codes attached to unsafe areas. We offer instrumentation and unsafe area services that remain in compliance to newest AS/NZS and global sector criteria.

Report this page